Why America Will Never Take Back the Rare-Earth Industry

From Aluminum to Rare Earths, This Is a War of Systems, Power, and Time

1. The problem isn’t the mine, it’s the system

America has rare-earth mines. The Mountain Pass mine in California still operates. But the ore ends up being shipped to China for refining. The issue isn’t geology, it’s structure.

Rare earths are not oil. You can’t dig them out and sell them. They require a full industrial chain: mining, separation, refining, chemical purification, and downstream processing into magnets, motors, and electronics. If one link is missing, the entire chain fails. What the United States lost was not a factory, but the foundation that holds the entire chain together.

2. Aluminum collapse and the hidden link to rare earths

Few people realize that part of the rare-earth supply is tied to aluminum production. Not all rare earths come from aluminum, but several key light rare-earth elements such as lanthanum, cerium, and neodymium, are often recovered as by-products from alumina refining. During this process, a residue known as red mud is produced, and this material contains measurable amounts of these rare-earth elements.

Under the Bayer process, every ton of alumina yields about 1.2 tons of red mud, which typically contains 1,000 to 2,500 ppm of rare-earth oxides. That translates to roughly two to three kilograms of recoverable rare earths per ton of aluminum produced.

China produces about 44 million tons of aluminum each year. The United States produces less than 700 thousand. On paper, that means China can recover around 110 thousand tons of rare earths from by-products annually, while the U.S. might reach 1,700 tons. The gap is two orders of magnitude.

This isn’t just about mining capacity. It’s about the industrial ecosystem. China’s vast aluminum output generates a steady flow of by-products that can be refined at scale. The United States, after decades of deindustrialization, no longer has that upstream base. Without it, even advanced technology has nothing to work with.

3. Aluminum refining needs energy and infrastructure

Aluminum refining is one of the most energy-intensive processes on earth. Producing one ton of aluminum requires about 15 megawatt-hours of electricity. That means the backbone of any rare-earth refining system is not the mine, it’s the energy grid that powers it.

China built that system. It has cheap, stable energy from hydro, nuclear, solar, and wind, connected by ultra-high-voltage transmission lines that move power across entire regions. Industrial parks and chemical plants sit right next to power hubs. That keeps energy costs predictable and logistics simple.

The United States doesn’t have that. Its electricity market is fragmented, expensive, and privatized. High energy prices make both aluminum and rare-earth refining unprofitable. Without affordable power and heavy industrial coordination, the U.S. cannot rebuild large-scale refining capacity.

4. Where those rare earths end up

The rare-earth elements derived from aluminum refining power modern life.

Lanthanum drives hybrid and electric-vehicle batteries, improves optical glass, and catalyzes petroleum refining.

Cerium enables catalytic converters and chip polishing.

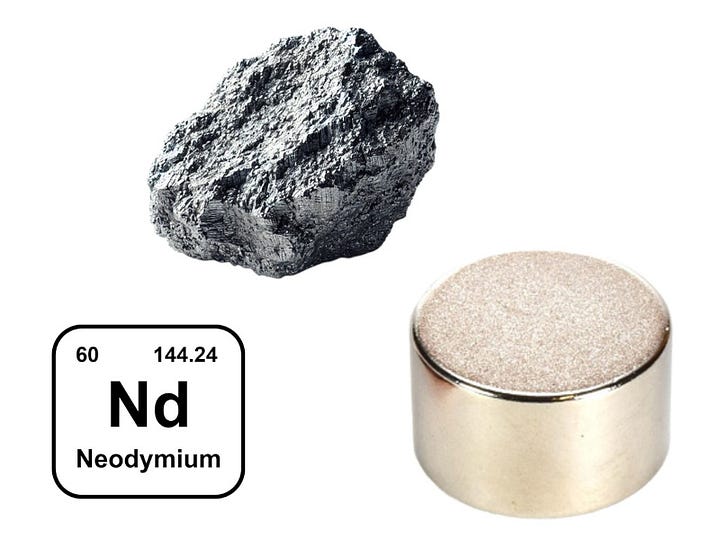

Neodymium powers permanent magnets used in EV motors, wind turbines, hard drives, radar systems, and missile guidance.

These three connect transportation, energy, and defense. Without them, every part of the clean-energy and military-industrial chain starts to weaken.

5. The U.S. and Australia deal changes nothing

Washington recently signed a new rare-earth partnership with Australia, promoting it as a step toward “strategic independence.” On paper, it covers both mining and refining. In reality, it’s aimed at military supply security, not industrial recovery.

China’s export restrictions already limit the use of certain rare-earth elements in U.S. weapons systems. So this deal is an attempt to replace that Chinese supply line with an Australian one, specifically for missiles, fighter jets, and radar components.

But here’s the problem: refining rare earths requires the same energy, infrastructure, and supply chain as aluminum. Without cheap power, chemical capacity, and industrial scale, the U.S. cannot match China’s system. The agreement may fund new facilities, but they will operate on imported materials and higher costs. That’s not independence. That’s outsourcing with a flag.

American taxpayers should recognize this pattern. These emotional, patriotic headlines are how politicians siphon tax dollars into symbolic projects that solve nothing. The real challenge isn’t in the ground. It’s in the system that turns ore into usable material.

If the United States wants to truly rebuild its rare-earth and aluminum ecosystem, it would take thirty years of uninterrupted effort, about the same time China spent building its current system.

6. The system decides everything

The rare-earth struggle is not about resources. It’s about systems. To take back this industry, the United States would have to rebuild its industrial base from the ground up, including factories, energy, labor, and education. That means decades of effort and trillions of dollars.

For forty years, America chose financialization, outsourcing, and de-industrialization. The result is clear: money without factories, mines without refineries, policies without systems.

Rare-earth independence will not happen because rare earths were never the point. The system was.

I hate to root against my country bur I hope that some so-called leaders will recognize their aggregious strategic errors and begin to fix it It is staggering how billergerant we are and appear not to see that China just needs to close its ports and the US is in serious trouble. Sadly Trump's is far to stupid and arrogant to wrestle with this issue. Love your work Neil.

Instead of ‘fearing’ China why not admit their superiority and work together for the good of all. I’ve heard China China China my whole life. They have been around the block many times over. And it shows. Let’s learn something from China. Start with health care and education.